Printing foldable objects

It was not long after I started printing some desired objects that I hit the snag of overhang. For example, I want to print a small box to contain some playing cards. Most of the structure is straight forward but an obstacle is the roof. No matter which way the box is orientated, an overhang exists. Of course, there is numerous ways to tackle this issue. One approach I am experimenting with is to print a part that can be folded into shape.

I did try googling the subject but I still did not get any clear parameters to use. Hence my need to do some experimentation.

In FreeCAD, I did a quick part using 3mm height and with a 90° wedge placed between two sides. The wedge is placed at 0.5mm above the bottom.

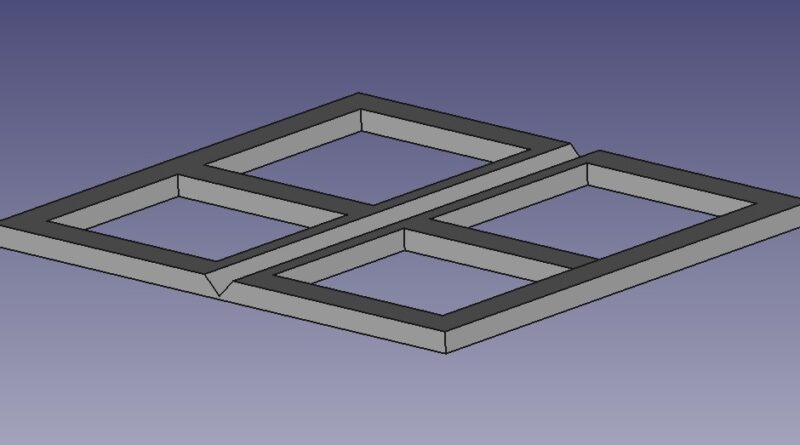

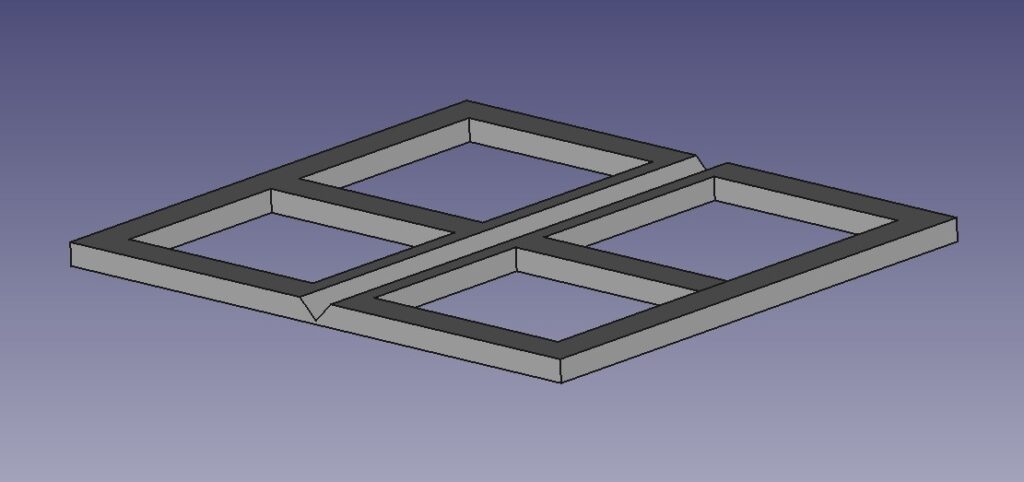

Here is the part in FreeCAD:

From my print, using PLA, I had a few observations…

- Firstly, the 3mm height was not needed for structural strength I needed. I will be able to reduce that.

- When bending into the wedge, I felt the plastic give way. I believe that means 0.5mm is too thick. Bending it after that point seems ok. I can bend it repeatedly without it splitting in any noticeable way.

- When bending into the wedge, the part wants to bounce back. Hence it seems that 90º is not enough to allow a 90° bend. Interestingly, bending the part in the opposite direction was fine and it would hold a 90º bend. Of course, a chamfer appears when bent in this direction.

With the next few iterations, the main problem seems to be with my FreeCAD skills or maybe a glitch in the program itself. I created the wedges for the corners by inserting a segment of a cylinder and positioning the cylinder so subtracting it from the model resulted in the required wedge. However, while this mostly works, each time I have printed the result I have had a remaining wedge left in place. That is, it was not subtracted from the model. Apart from this annoyance, the next few iterations were improvements. Changes were:

- Adding the missing walls and the bottom to make five sides of a cuboid.

- Reducing the wall thickness from 3mm to 1mm. 3mm was overkill for this application.

- Increasing the size of the wedge from 90° to 92°. This did indeed improve the bends but I need to improve the model to be sure it is the best angle to work with.

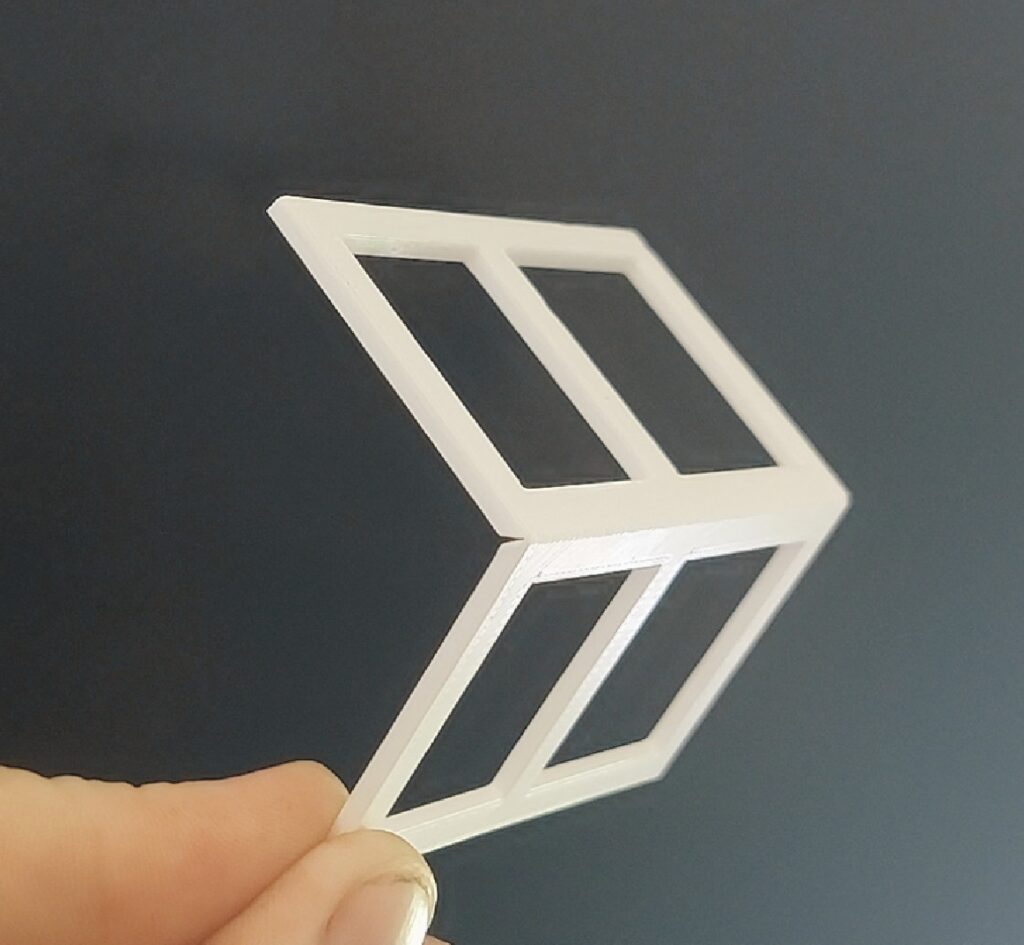

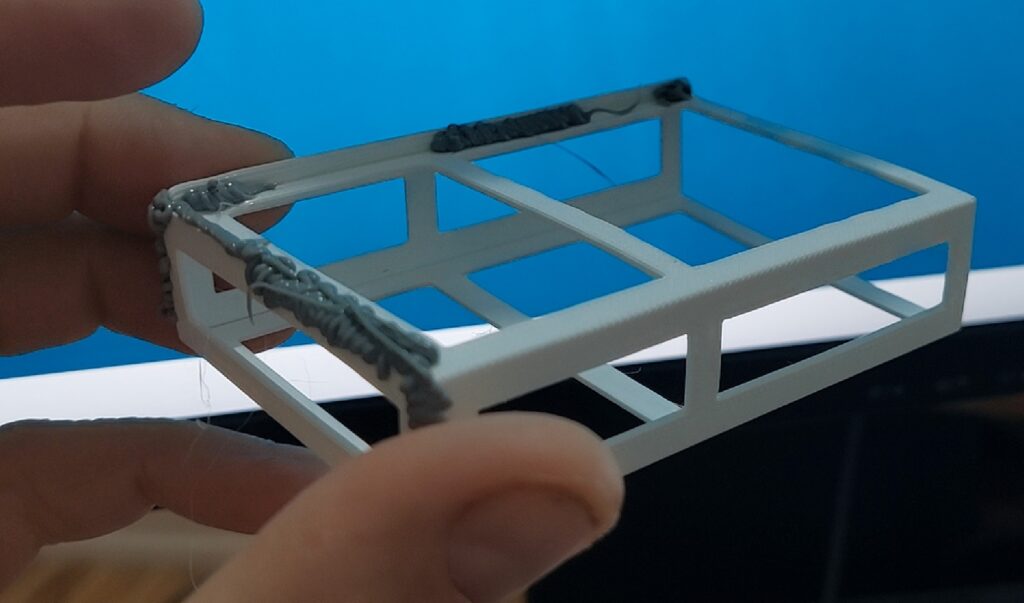

Here is the 2nd iteration. A few obvious mistakes can be seen including incorrect length on the side and the presence of the wedge I described above.

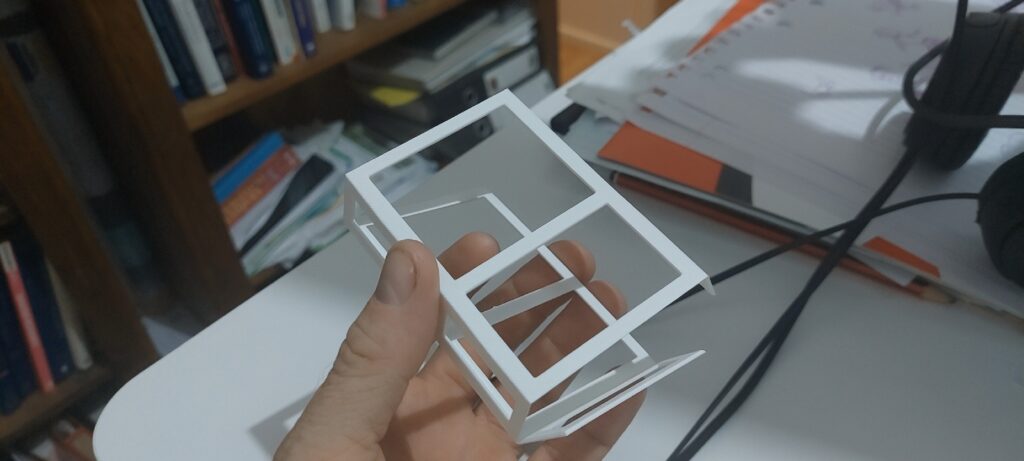

This was the third attempt:

I added some filament from a 3d printer pen to hold it in position. Mostly this was fine except for the remaining wedge issue again. A deck of cards fits in nicely.

Next iteration finally got the cuts/wedges in the right orientation. This version was largely as desired but I had reduced the wedge angle to 91º and I find the corners still want to bounce out a little. It is acceptable but I think going 92º produced the best results.

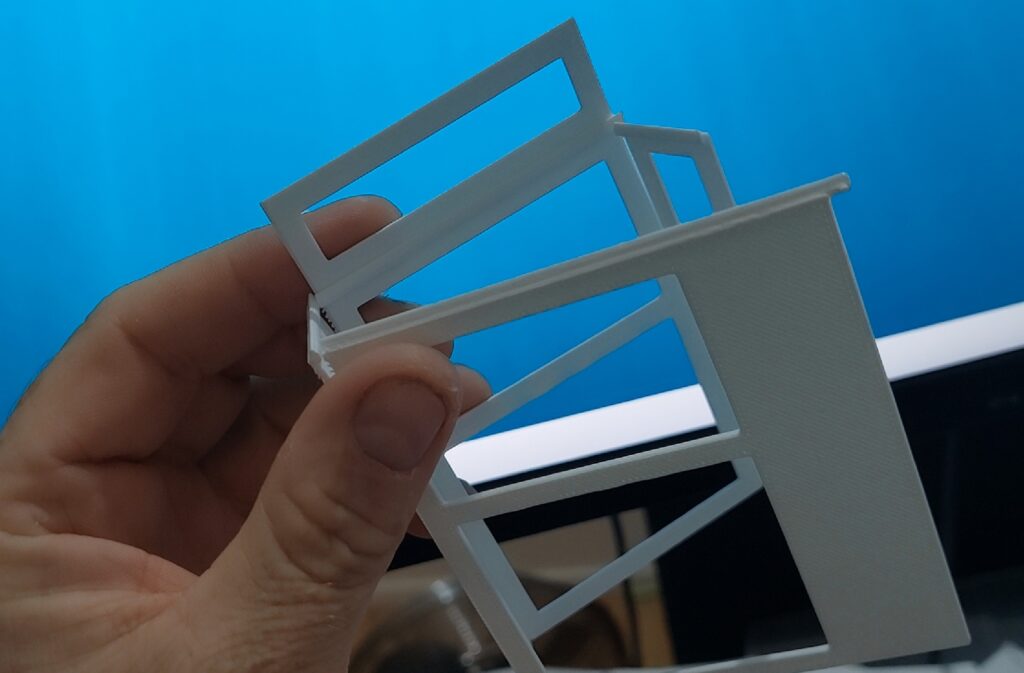

Here is the print:

This was the desired product. Now to add some features to make it a superior container for a deck of cards.